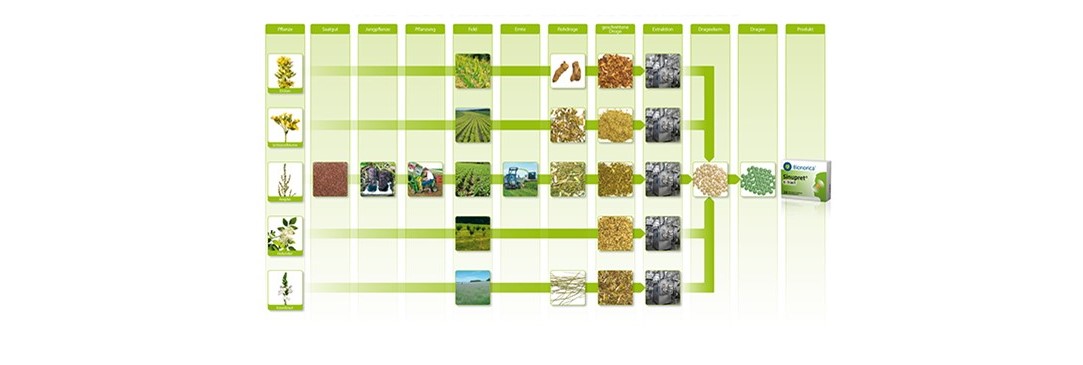

- It all starts with the seed

- Medicinal plants grow best in their natural habitat

- High-quality in further processing through patended methods

- Respect for nature

The quality of medicinal plants is at the heart of Bionorica’s strategic orientation. The research, manufacturing and use of excellent raw materials make Bionorica and its products unique worldwide.

Everything starts with the seed

Our work begins well before cultivation. Selecting the “right” plant from a pharmaceutical perspective can be very complex. For example, in the case of thyme, not all thyme are the same. There are numerous plants within each plant type, which differ in their appearance, smell, and composition. Not every plant is suitable for the manufacture of a phytopharmaceutical. Cultures of naturally occurring plants are created and checked for their suitability. If plants with a suitable ingredient pattern are found, their seeds are used for their own breeding. The search and optimization of the seeds are the result of years of work, which is carried out in close cooperation between universities and scientists at Bionorica SE.

Medicinal plants grow best in their natural habitat

In the next step, the optimal location for cultivation is determined. To do this, factors such as soil type, climate or environmental impact must be taken into account. In general, the choice of location, young plant breeding, cultivation management and plant protection must be adapted to the respective needs of the plant because only then can it develop optimally. Our medicinal plants are cultivated where they are endemic, whenever possible. For example, rosemary feels “comfortable” on Majorca, gentian in France.

The time of harvest also has a major impact on quality because the composition of the ingredients is not identical in every stage of vegetation of the plant. To determine the right time, the ingredient sample is determined with modern analysis devices. In addition, other factors such as weather conditions or the age of the plants are taken into consideration.

This standardization enables Bionorica to achieve the desired quality and optimum mixture of the complex ingredients. Only cultivation partners who meet the high quality standards set by Bionorica as well as the legal requirements (GACP guidelines) may cultivate for us. In addition to passing an audit and regular checks, the cultivation partners must provide seamless documentation of all steps during cultivation (e.g. seeds, seedling cultivation, planting, fertilization) and post-harvest processing (cleaning, cutting, drying).

High quality in further processing through patented methods

The care Bionorica takes when developing its own seeds and the controlled cultivation of medicinal plants are also a matter of significant importance when harvesting and processing the plants. The decisive factor is the subsequent drying process, which has a major impact on the quality of the medicinal plant and its active ingredients. We rely on the latest processes and techniques. For example, we have developed a specific vacuum drying process that preserves the high content of essential oils and flavonoids in the extract. In this way, the multilayered, native substances of the plants are preserved across all production stages and can develop their full effectiveness in herbal medicinal products. These manufacturing techniques are patented.

Respect for nature

Nature is our most important supplier of raw materials. It goes without saying that we have the greatest respect for nature in every aspect. Sustainable processing methods developed by Bionorica such as the energy-saving processes for concentrating liquid extracts and environmentally friendly solvents such as ethanol ensure that natural resources are handled responsibly.